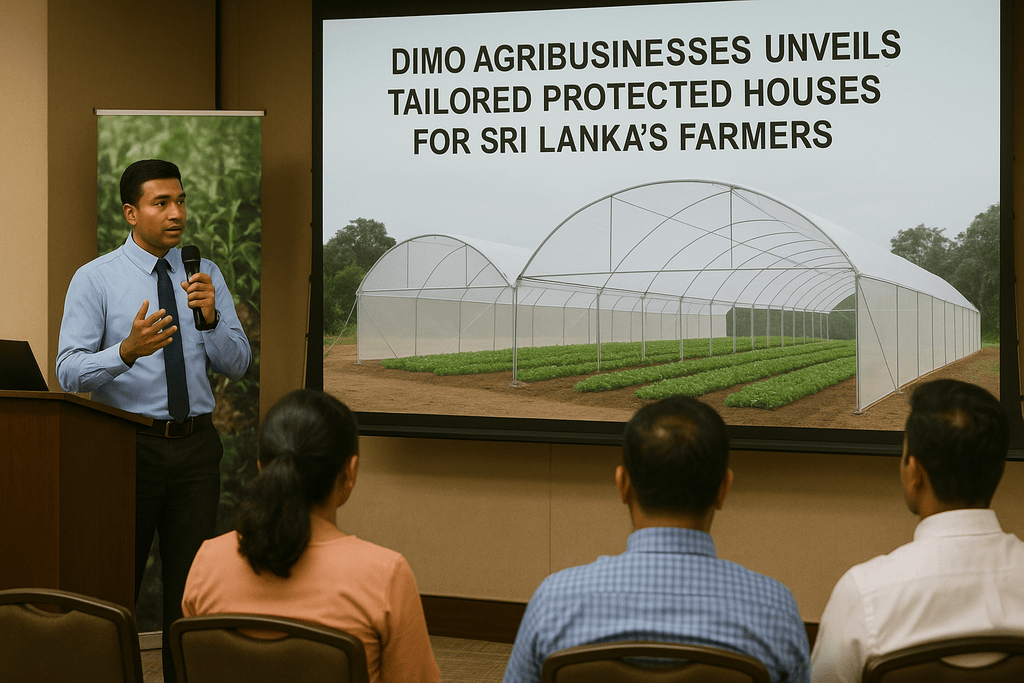

In the face of shifting weather patterns and their increasing toll on agriculture, Sri Lanka’s DIMO Agribusinesses has rolled out a suite of practical tools aimed at making farming more adaptable. Operated under its DIMO Agritech Unit, the initiative focuses on customized protected houses and polytunnel models that offer farmers crop-specific environments tailored for different climatic zones across the island.

At the core of this effort is the understanding that climate variability is no longer a distant concern but a pressing daily reality. As rising temperatures, erratic rainfall, and pest outbreaks begin to severely impact yields, many cultivators are seeking structured, manageable alternatives that can help them preserve and enhance productivity. Priyanga Dematawa, Chief Operating Officer of DIMO Agribusinesses, explained the rationale behind their approach.

“Climate change increases crop damage which needs crop specific solutions. We have introduced modern protected houses that are well suited for the lowland, wet and dry zones, as well as for the upland and intermediate zones.

Adapted Structures for Distinct Agro-Climatic Zones

DIMO Agritech’s protected houses are not one-size-fits-all installations. Instead, they are thoughtfully engineered to suit Sri Lanka’s diverse terrain, which includes lowland wet and dry zones, as well as upland and intermediate regions. The variations in elevation and humidity levels in these zones create unique cultivation challenges, and the company’s new models aim to help growers navigate these conditions more efficiently.

In the lowland wet and dry zones, for instance, the newly introduced protected house model features Shield curtains and a fan-based ventilation system. These side coverings are equipped with polythene curtains that can be adjusted in tandem with air circulation needs. The curtains can be raised or lowered to work in sync with the installed fans and natural airflows, helping farmers maintain favorable temperature and humidity levels inside the house.

This attention to micro-environmental control makes it easier for cultivators to grow crops that would otherwise struggle in open fields, particularly during periods of excess rainfall or extreme heat. The built-in drip irrigation and fertilizer application system also allows farmers to manage their resources more precisely, minimizing water wastage and optimizing nutrient delivery.

High-Value Crops Within Reach

One of the most practical outcomes of this new model is its potential to support the growth of high-value crops. Farmers interested in cultivating bell pepper, salad cucumber, and tomato—particularly in the upland wet zones—can benefit from the well-regulated environment offered by the protected house. These crops, often susceptible to temperature swings and pest infestations, require more care than conventional field-grown varieties. The new units help create a buffer between the external environment and the crops, offering a more consistent growing condition.

In the upland and intermediate zones, where temperature variation can be significant, DIMO’s protected houses are equipped with a different configuration. These units are designed with insect-resistant netting and come in two distinct roof styles to better match local ventilation needs. Additionally, a cooling system is integrated to manage internal heat levels—especially important during hotter months or in areas that receive direct sunlight for extended periods.

Guidance and Materials to Support Every Step

Beyond just selling the infrastructure, DIMO Agritech is also offering what it sees as a full-circle solution for growers. Farmers investing in these protected houses receive access to advanced water-soluble fertilizers that are matched to the specific crops being cultivated. They are also supplied with seeds and planting material, as well as guidance on pesticide use and pest management.

Dematawa emphasized the company’s commitment to supporting cultivators not only during the setup phase but throughout the cultivation process. “DIMO Agritech provides all the advanced water-soluble fertilizers required for any crop grown, along with specific crop guidelines. Our company also provides the seeds and planting material required for cultivation, as well as guidance on pesticides and pest management,” he said.

Another component of the setup is the use of special ground covers. These are intended to maintain a hygienic and weed-free environment inside the protected house, while also improving drainage—an important factor in avoiding root diseases and maintaining crop health.

Technical Support for Long-Term Success

Recognizing that technology alone cannot drive success, DIMO has also committed to offering comprehensive technical assistance. The team includes both local and international technicians with experience in protected cultivation. These experts are available to guide farmers through various stages of their production cycle, from planning and planting to monitoring and harvesting.

This support network is designed to help farmers get the most out of their investment, especially those who are new to controlled-environment farming. The presence of an experienced support team can make a significant difference, particularly when fine-tuning factors like irrigation frequency, nutrient schedules, and pest monitoring systems.

Also Read: Satellite Monitoring: How Banks Use Space Data to Assess Farm Lending

Scaling for Commercial Viability: A Measured Step Toward More Sustainable Farming

While protected cultivation is sometimes associated with small-scale, boutique-style operations, DIMO Agritech is encouraging larger-scale implementation. According to Dematawa, investing in a house of at least 2,000 square feet offers a reasonable balance between cost and productivity. However, going beyond that size can lead to more promising returns.

He noted that, “Investing in a house of at least 2,000 square feet is more effective, while a house of more than 4,000 square feet can yield greater commercial returns in 2-3 years.” For many growers aiming to move from subsistence to commercial farming, this presents an opportunity to scale gradually while learning the ropes of protected cultivation.

In offering this new range of protected house models, DIMO Agribusinesses is taking a measured, practical approach to the evolving needs of Sri Lankan farmers. By addressing zone-specific challenges, combining infrastructure with technical guidance, and promoting both small and commercial-scale adoption, the company aims to make smart farming practices more accessible.

As climate challenges continue to mount, such structured, adaptable solutions offer cultivators a clearer path forward—one that respects the local context while providing tools to enhance productivity and crop resilience.